Weathering The Storm: Hurricane Helene’s Impact On CPG

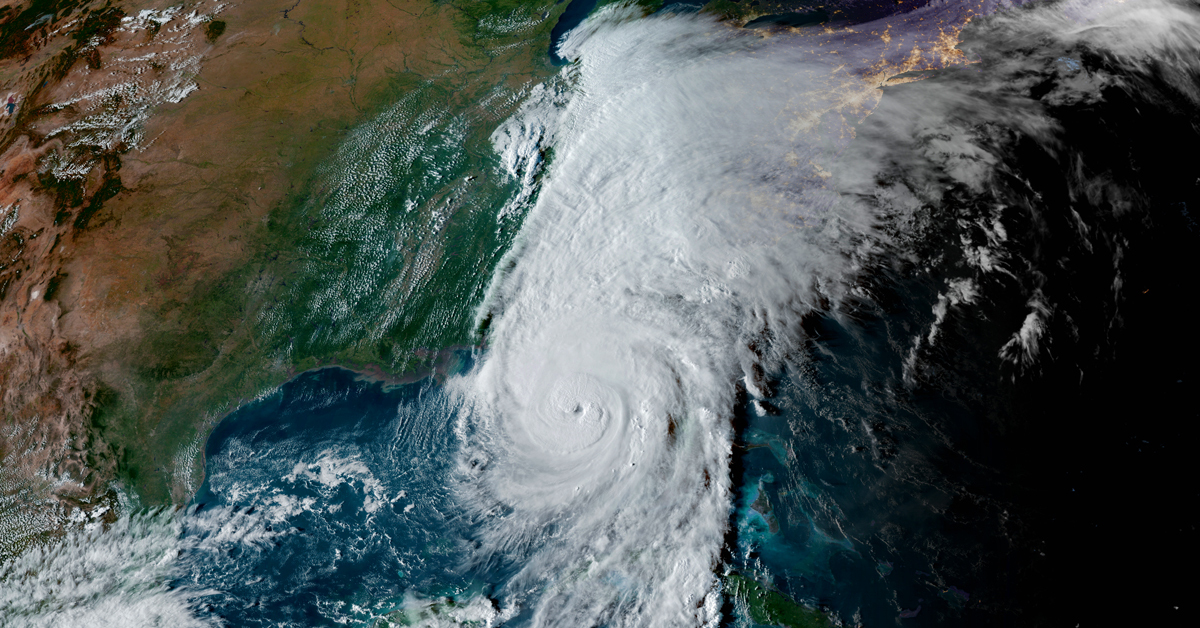

What was it like for CPG businesses to bear the brunt of a once-in-a-thousand-year hurricane? In the wake of Hurricane Helene’s devastating impact, we spoke with a handful of brands from North Carolina to hear how they are rebuilding from loss through communal support and entrepreneurial resilience.

On September 26, the hurricane made landfall in the Big Bend region of Florida and proceeded northeast on a path of destruction that decimated the southern Appalachian region of North Carolina. The force of the storm breached reservoirs and waterways while bringing down trees which took out electricity, internet service, and water access for days or weeks.

North Carolina Governor Roy Cooper announced that there was likely over $53 billion of damage to the state. In its October 23 assessment, the North Carolina Office of State Budget and Management calculated the indirect and direct costs of business disruption will be over $13 billion.

Beer City Runs Dry

Known as “Beer City,” Asheville is a hotbed for craft breweries, including New Belgium’s campus brewery sitting alongside the French Broad River.

The company did not comment on the scale of the damage to its facilities but it has closed its taproom and asked patrons to not visit as “remediation efforts have begun” with clean-up anticipated to “take some time,” according to a New Belgium spokesperson.

“We have been in communication with our business partners and expect there to be disruptions to our order fulfillment capabilities for the next several weeks,” the company told BevNET in late October. “Our teams will be doing everything we can to mitigate these disruptions to the best of our ability and there is an enormous amount of work being done to maximize both our production and fulfillment capabilities across our network.”

Along with repairing its brewery, New Belgium has also been distributing potable and non-potable water to the community while also committing financial support to local organizations and disaster relief funds.

One of those relief funds, Higher Calling, was set up just after the hurricane by craft brewery Dssolvr. The initiative is asking the greater craft beer community to donate to its peers who are rebuilding in Western North Carolina.

Along with crowdfunding efforts, the Asheville Brewers Alliance (ABA) has been organizing the local craft beer community to help with the rebuild by using breweries as distribution sites for potable water and for donated goods, such as food, water and other essentials.

ABA executive director Karis Roberts reported that craft industry professionals have brought valuable skills like forklift and pallet jack operating to help clean out buildings and help with relief distribution.

It is unclear when potable water will return to the area but an update last week from Asheville City Council member Maggie Ullman said it could be as early as a few weeks to mid-December. As the exact timetable remains uncertain, some breweries have been sharing the cost of bringing in water tankers to use in brewing but not at scale yet.

The long-term impact on the region’s craft beer industry remains to be seen if potable water doesn’t become readily available. Already, Wicked Weed Brewery has closed its Funkatorium taproom and Cultura restaurant indefinitely due to the challenges. The brewery remains open but on-premise is difficult when there are no tourists and a lack of drinking water, Roberts said.

Visitors to Asheville’s Buncombe County generated about $3 billion in revenue for local businesses in 2023, according to data provided by Explore Asheville. Tourism revenue represents nearly 20% of the county’s GDP.

Businesses Washed Away

Many companies that experienced significant losses have started their own crowdfunding campaigns to support business recovery efforts as they negotiate what will be covered by insurance claims.

Asheville Tea Company watched its production facility and warehouse get pulled off its foundation and carried down the Swannanoa River during the flooding. Even though the company lost all its inventory and equipment, it is trying to find space to rebuild and using donations to slowly restart operations.

The company’s founder and CEO Jessie Dean posted a video recently announcing the company was researching co-manufacturers and is in contact with local farmers and suppliers to release some of its holiday season varieties to consumers by the end of the year.

Before the hurricane swept through Western North Carolina, Sarilla — another local tea company that makes both loose-leaf and canned sparkling teas — had recently received its first full shipping container of tea from Rwanda.

After Sarilla’s warehouse in Swannanoa, N.C. was damaged, tea inventory was lost. On the positive end, the supply at the company’s fulfillment center near the Asheville airport in Fletcher, N.C. was unharmed, even though other buildings just a couple hundred feet away were demolished, said Sarilla founder Sara Stender Delaney.

“This is part of the emotional devastation,” she said. “This is the situation in our entire region, you just don’t know what you’re going to see when you turn the corner.”

Sarilla sells its products locally both as a wholesaler as well as in local retailers and it is already feeling the sales impact as many of its partners have closed temporarily or indefinitely.

Supplying The Supply Chain

Headquartered in Marshall, N.C., FedUp Foods, the makers of Buchi and Wild Pop, is one of the country’s largest private manufacturers of fermented beverages.

Though the company’s facility was not directly impacted, Marshall — located about 23 miles north of Asheville with a population of around 800 people — was almost completely washed out as flood waters crested around 27 ft. and ran right through Main Street.

In the immediate aftermath of the flooding, FedUp Foods CEO David Gray tried to implement a methodology that friends in leadership roles in the armed forces taught him.

“It is about immediately understanding, where your people are at, what are their needs and solving around that,” he said. “But after a while, that starts to wear, and we’re starting to now see the beginning of the fatigue and stress set in.”

FedUp Foods was been able to resume operations at its facility once power was restored and it could source potable water. Yet, getting the plant to run at capacity has been difficult because staff face continued challenges due to school closures and roads still being repaired.

The company operates two other facilities. FedUp Foods’ second production plant is about 50 miles north in Erwin, Tenn. It was also impacted by a dam breaking that destroyed a bridge on the highway connecting Erwin and Marshall. The company recently finished construction on its third plant in Wilmington, N.C. which began production this past week.

“Things that we really focused on in the last couple of years is our redundancy, across our supply chain,” Gray said.

Launched in 2021, soup brand 18 Chestnuts had just “hit its stride” when the hurricane hit, said founder Steven Kossoff. After its best month ever in August, the company was already tracking to do 50% more sales in September with new partnerships with Whole Foods and Fresh Thyme placing purchase orders.

The brand did not lose its facility but similar to other producers, with no water, electricity, cellular service or internet “everything came to a screeching halt.”

Mobilizing quickly to get soups made, 18 Chestnuts was able to use the Food Lab facilities at the University of North Carolina’s Kannapolis campus until it was able to onboard with a co-manufacturer in Raleigh.

“Comparatively to other companies, we fared very well,” Kossoff said. “We didn’t lose any product, we didn’t lose any raw ingredients, but what we lost was critical production days in what is now the height of soup season.”

The Cost To Rebuild

For small producers like Darë Vegan Cheese, rebuilding is not just about cleaning up and restarting operations. It also includes negotiating a new challenge: insurance claims.

“Right now, my insurance is using every language that they can to try to confuse me on what they will claim,” said founder Gwendolyn Dare Hageman. “What I am certain of is that they will claim $9,000 so that is helpful, but it is certainly not remotely close to what our loss is.”

Hageman calculated that between about $35,000 in lost inventory and ingredients along with revenue loss for October, the storm’s total economic impact was around $100,000 for Darë Vegan Cheese.

Her Weaverville, N.C. facility did not flood in the wake of Hurricane Helene but it did lose power and was inaccessible due to downed trees and runoff for days. Hageman was able to salvage some of her frozen inventory about five days after the storm but most of her product was lost when cold storage went down.

Hageman’s team has been working to get as many orders out after remaking its cashew milk cheese cultures from scratch. The brand’s distribution partners have been understanding, Hageman said, offering smaller weekly pickups as opposed to Darë having to drop full pallets off at distribution facilities.

“To be honest, the build-back process is going slightly faster than I expected,” she said. “We have a massive backlog of wholesale outside of our distributors that we will start tackling next week. We do a lot of shipping to retailers so we haven’t even begun to scratch the surface of what our backlog is there.”