New Harvest: Cultured Meat to Unlock Sustainable, Unique Protein Sources

New Harvest, a non-profit dedicated to advancing cellular agriculture in food and beverage, addressed one of the leading questions for the biotech industry: how can cultured protein be readily accessible to consumers without causing more harm than conventional agriculture?

Recently, New Harvest hosted its first in-person conference since 2019 at NewLab in Brooklyn. During the two days of panels, discussions and presentations, a persistent focus was how to further innovation in cultured proteins. Topics ranged from solving the scalability problem to adopting more open sourced research to how animal rights play into the nascent industry. Two sessions addressed head-on the concept of harm in the cultured meat sphere by expanding the concept of how and what can be an alternative to conventional meat and how.

Cultivated Meat As Climate Tech

Up until now, most cultivated meat has been grown using fetal bovine serum (FBS), a protein-rich ingredient that is typically sourced from the meat industry. The serum is used to grow animal cells in a bioreactor to create what has been called at times, lab-grown meat.

Future Fields is one company addressing the need for an environmentally sustainable alternative to FBS that does not rely on conventional meat production.

Matt Anderson-Baron, Co-Founder of Future Fields, asked the audience to consider critically the true environmental ramifications of growing cultured meat at scale. To feed just 10% of the U.S. meat market, Future Fields estimates cellular agriculture will require 13,000 tonnes of recombinant proteins (growth media like FBS) per year, he said.

“Even if our math is a little off here, we are still looking at a pretty big gap in the supply chain.”

Anderson-Baron argued that labeling cultured meat as “animal-free” could pigeon-hole the industry in a paradigm where creating animal-free serum is not environmentally sustainable.

Future Fields’ Ento-Engine platform aims to provide solutions to creating a low-carbon supply chain for growth factors. It addresses the problem of growth medium by genetically engineering fruit flies as a scalable source of recombinant protein. Not only is the platform more ethical than relying on FBS as a growth medium but it has “a 700x to 3000x smaller GHG footprint than existing bioreactor technology,” according to Future Fields. “To create a low-carbon supply chain for growth factors.”

The Case For Cell-Cultured Elephant

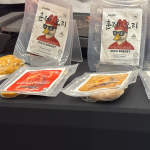

Australian cultured meat company VOW has been built on the supposition that a lab-grown alternative to conventional meat should not be boxed in to what animals have been domesticated for meat consumption.

At the New Harvest conference, VOW Co-Founder and CEO George Peppou questioned why cultured meat companies are choosing to make products that almost exclusively mimic conventional beef, chicken or pork products. “By sticking with just the major domesticated animals, we’re not setting ourselves up to produce the cheapest possible cell mass in scale. And we’re not setting ourselves up to make the tastiest possible meat that we could,” Peppou said.

The answer to why these traditional meats is simple: to meet customers where they are today.

Peppou explained that even though most plant-based meat has been well-received as a comparable substitute for real meat or poultry, humans continue to eat increasingly more amounts of conventional meat.

Thus, if cellular agriculture companies aim to change how humans eat meat, they must aim to change consumer behavior by inventing an abundant supply of entirely unique meats that are only available through cellular agriculture technology, Peppou argued.

VOW attempts to solve this by building a wide-ranging library of animal cells that treats those cells as potential ingredients that “can be combined in ways that animals can’t, to make food that is tastier, more nutritious or more functional that what animals make,” Peppou said.

“How much better is that than making another chicken nugget?” he said.